Supplies

Tools |

| TRLab is equipped with machinery and equipment for testing materials, elements and finished products. All the instrumentations are subject to maintenance schedule and periodical calibration checks, with the intervention from laboratory and certified calibration facilities SIT with a variable periodicity between 12 and 18 months. |

|

|

|

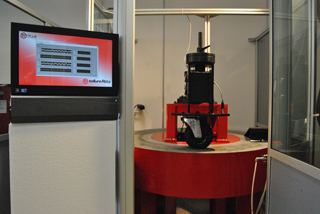

TESTING GROUND FOR WHEELS AND CASTORS FOR INDUSTRIAL USE

|

|

It is used in order to test the wheels and castors dynamic capacity for industrial use , according to the ISO 22883:2004 ed ISO 22884:2004 (points A-B-C), on between 80 and 300 mm diameter wheels, for variable capacity rates from 20 to 2500 daN; the test velocities are settable from 2 to 24 km/h allowing test runs at different speeds also provided by legislations. |

|

|

|

TESTING GROUND FOR WHEELS AND CASTORS FOR INSTITUTIONAL AND DOMESTIC USE

|

|

|

TESTING GROUND FOR WHEELS AND CASTORS FOR WASTE BIN CONTAINERS

|

|

It is used in order to make the dynamic testing with drop step, according to legislation EN 840-5:2004, section 4.9.3, regulating wheels and castors requirements, used in mobile containers for waste collectioni. The test is executable on complexes with variable diameter wheels from 160 to 250 mm, with vertical load from 50 to 85 DaN. Velocity 3,3 Km/hh. |

|

|

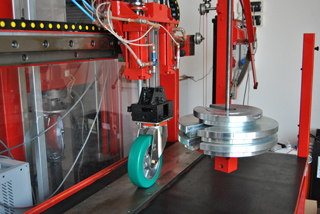

TESTING GROUND FOR ROLLING RESISTANCE AND INRUSH

|

|

It is used in order to make:

- Rolling resistance test, made according to legislation UNI 11330, on complexes with variable diameter wheels from 60 to 250 mm, applying a variable vertical load from 20 to 1000 DaN. The measurable driving force can be variable from 1 to 35 DaN;

- Braking efficiency test, made according to legislation ISO 22883 e ISO 22884, on complexes with variable diameter wheels from 60 to 250 mm, applying a variable vertical load from 20 to 1000 DaN and a variable driving force from 5 to 200 DaN;

- Braking efficiency test made according to legislation legislation UNI EN 1004:2005, section 7.5, regulating usable mobile scaffolding products;

- First ex dynamic grip test on powered wheels. |

|

|

ELECTRICAL DYNAMOMETER

|

|

It is used in order to make:

- Traction, tearing and compression tests aimed to characterize elastomeric materials

- Static load tests on variable wheels and castors up to 25 KN, according to the legislation UNI EN 1004:2005, section 7.5, regulating usable mobile scaffolding products.

Tests are executable on complexes having a nominal capacity up to 800 DaN, diameter wheel from 80 to 250 mm and “wheel + castor” total high up to 500 mm. |

|

|

PRESSA COLLAUDO CARICO STATICO

|

|

Used in order to make static load tests on variable cargos between 1.000 and 20.000 daN, on variable diameter wheels up to 600 mm. |

|

|

"FATIGUE" TEST MACHINE

|

|

It is used in order to verify if wheels are deteriorated after 10 millions rotation (and more), also with high speeds.

Tests are executable on wheels with diameters up to 200 mm, applying a load of max. 1000 kg, with speeds up to 6-10 km/h.

With higher speeds, applied load has to be lower (max. 300 kg at 40 km/H speed).

|

|

|

POSITION FOR BRAKING TEST

|

|

Braking system fatigue tests are carried out according to the legislations ISO 22883:2004 e ISO 22884:2004, on complexes having diameter wheel from 80 to 250 mm; the test is also executable according to the legislations ISO 22881:2004 and ISO 22882:2004, without direct control on the applied load.

|

|

|

FOG-SALT CHAMBER

|

|

Used in order to test the accelerated corrosion resistance , according to UNI ISO 9227, to verify the quality of protective finishing applied made of electro-galvanizing, phosphating, spray coating, powder coating, zinc security flap, etc.

|

|

|

EQUIPMENT FOR VERIFYING MATERIALS

|

|

The laboratory is provided also with:

a) instrumentation in order to verify the electrical resistance on antistatic components;

b) instrumentation in order to verify the main elastomers’ physical and mechanical characteristics (hardness A and D, resiliance, density, abrasion resistance);

c) basic instrumentation to control dimension.

|

|

|

SENSORS AND VIDEO-RECORDING

|

|

Instrumentation provided are integrated with:

a) sensors and software connected to a computer monitoring and registering the tests made in real time;

b) video-recording video-recording system of functional and performance tests.

|

|

|

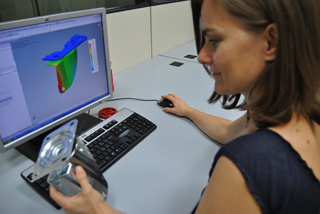

SOFTWARE FOR DESIGN AND BEHAVIOR SIMULATION

|

|

For design and behavior simulation stages are used:

a) analysis FEM software positions;

b) made to measure software with prediction algorithm of components dynamic behavior.

|

|